Where are oil-type transformers used?

There are several types of transformers available on the market today, which come with their own respective pros and cons. Generally speaking, for medium-size transformers, the units can be categorized as oil-filled (liquid-type) or dry-type (solid state).

As the terms suggest, oil-type transformers use flammable liquids (usually mineral oil – but can also be hydrocarbons or silicone for other liquid types). Dry-type transformers do not use flammable liquids and rely on robust insulation to promote cool operating temperatures.

At a glance, one could assume that dry-type units, being solid state and not requiring flammable liquids, would be better than oil-type transformers. This is not always the case, as the latter type is considered to be more efficient, longer lasting and features more reliable overload capabilities. However, oil-filled units also come with their own set of limitations (for example, the transformers aren’t suitable for indoor applications).

Learn more about the difference between oil-type and dry-type transformers below.

Dry-type Transformers

As mentioned earlier, dry-type transformers require an insulating system that promotes air circulation to keep it cool. Because of this, the units are bigger and use larger coils than oil-filled models (with the same voltage/capacity ratings). Furthermore, dry-type variants use more materials, resulting in higher costs. When it comes to performance, the power distribution units operate at higher temperatures, since natural cooling mechanisms are not always constant and can easily be affected by the surrounding environment. These drawbacks result in a shorter lifespan (15 to 25 years for dry-type transformers, compared to 25 to 35 years for liquid-type models).

From a maintenance perspective, keeping dry-type stations in top working condition involves continuous inspection. Operators must closely check and clean the grills, louvers or slits to make sure they are not blocked. Overlooking this step can cause the machine to overheat. An advantage to this aspect of dry-type transformers is not needing to perform routine oil analysis (more on this later).

Recommended article:Industrial Paint vs. Decorative Paint: A Comparative Analysis

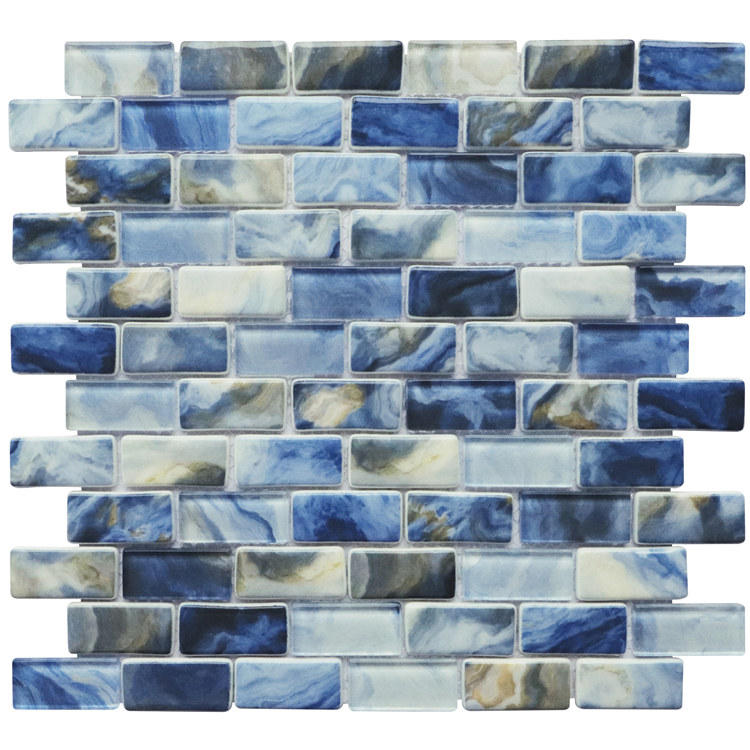

Dive into Elegance: 8 Best Swimming Pool Mosaic Ideas

With so many limitations related to dry-type transformers, why are they still around? Dry-type transformers are particularly useful for indoor locations and areas that are highly prone to fire-related risks. Moreover, the stations come with less regulatory requirements for installation, operation and maintenance, which come with their own set of costs to implement. This includes less fire safety guidelines to worry about during operation and storage.

Additionally, dry-type power distribution can be installed closer to the target area, due to less fire-related risks, translating to lower costs (less materials/cables needed for connection). Examples of such populated locations include hospitals, airports, underground power distribution systems, hospitals, malls and more.

Oil-type Transformers

Oil-type transformers use combustible liquids for cooling, making the units highly suitable for outdoor locations. This is where most of its limitations can be found. It is important to highlight that advancements in oil-filled transformer technology replaces flammable oil with more stable (less flammable) liquids, allowing the products to be used in locations with strict environmental standards. Regardless of the type of liquid used, oil and liquid-type transformers offer better cooling than dry types, because liquid is a more thorough medium for cooling applications. Highly efficient cooling mechanisms also translates to a smaller, more compact unit.

Perhaps the biggest advantage of oil-filled power distribution is that the units can handle higher ratings. Dry-type models are typically used for lower-rated applications.

Focusing on maintenance, oil-type models are subject to periodic oil analysis, in addition to cleaning and general inspection of working components. Repairing a liquid-type transformer is also considered to be less costly and easier.

What is the purpose of dams and their role in water management?

Scaffolding Cross Braces: Enhancing Structural Stability and Safety

Which industries commonly use GFS tanks, and what are the benefits of using them for storage purposes?

HDPE Pipe Floats: The Ultimate Guide to Buoyancy Solutions