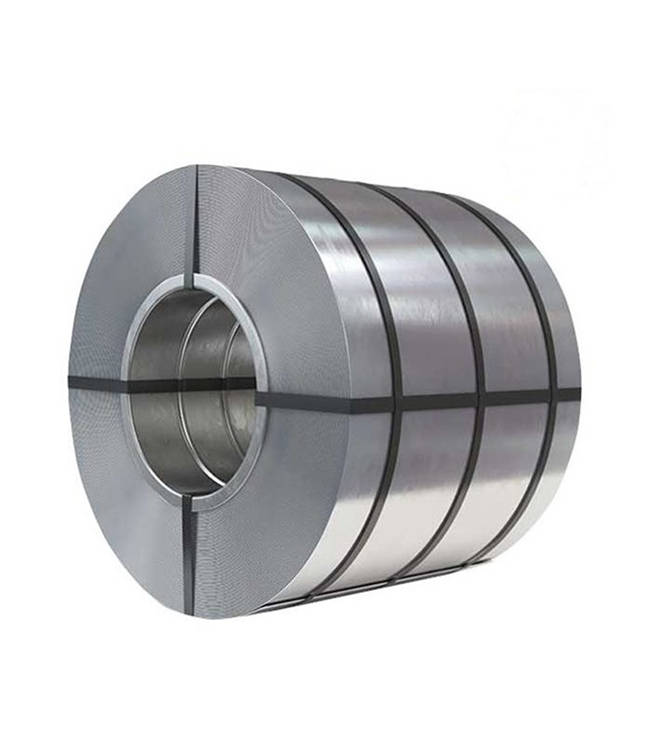

What is Cold Rolled Stainless Steel?

Cold rolling is a work hardening process used to change the structure of metals and is often used to process stainless steel. Cold rolled stainless steel as a raw material has a wide variety of applications in medical, aerospace and automotive engineering. Read on to learn more about what cold rolled steel is, how it's produced, and what it can be used for.

What is Cold Rolled Stainless Steel?

Cold rolled steel, sometimes abbreviated to CRS, is well-known for being an extremely ductile material, and is ideal for applications where precision is necessary. It is used in many applications, like household appliances, furniture, lockers, and filing cabinets. In construction applications, CRS is commonly used for building garages, steel sheds, and other industrial buildings.

In simple terms, cold rolling is the process of strengthening steel by changing its shape without using heat. Cold rolling, unlike hot rolling such as with hot rolled steel, can only occur when a metal is below its re-crystallization temperature. Where hot rolling is performed using high temperatures, cold rolling is performed at room temperature. Instead of heat, mechanical stress is used to change the structure of metal. Strain hardening can then increase the metal's strength by up to 20%, and can also improve a metal's surface finish.

Explore more:Construction & Real Estate

Dive into Elegance: 8 Best Swimming Pool Mosaic Ideas

During the cold rolling process, when the metal is put under mechanical stress, it causes a permanent change to the crystalline structure of the metal. This causes an increase in its strength and often improves corrosion resistance. Along with improving its surface finish, another advantage of cold rolling is better dimensional accuracy.

A cold rolled stainless steel coil can be precision manufactured, allowing the metal to be produced to extremely tight tolerances. The act of work hardening the stainless steel material through cold rolling allows us to achieve various levels of temper, such as quarter-, half- and full hard. The hardness level depends on how much cold work has been done on the steel. Quarter-, half-, and full hard stocks have greater amounts of reduction (sometimes up to 50%). This increases the yield point but decreases the ductility of the steel. Quarter-hard steel can be bent back over itself without breaking, while half-hard can be bent at a 90-degree angle, and full hard can be bent at a 45-degree angle without breaking it. Cold rolled metal is often used in applications where the metal needs to be bent without the risk of breaking.

What is the purpose of dams and their role in water management?

Scaffolding Cross Braces: Enhancing Structural Stability and Safety

Which industries commonly use GFS tanks, and what are the benefits of using them for storage purposes?

HDPE Pipe Floats: The Ultimate Guide to Buoyancy Solutions