How much does a pond liner cost

Establishing the cost for a small garden pond liner

It’s simple to establish the cost for a small garden pond liner: Basically sheet material like EPDM will cost around 75 cents per square foot, and this is perhaps the most common retail option for a garden pond measuring nearly 12′ x 12′.

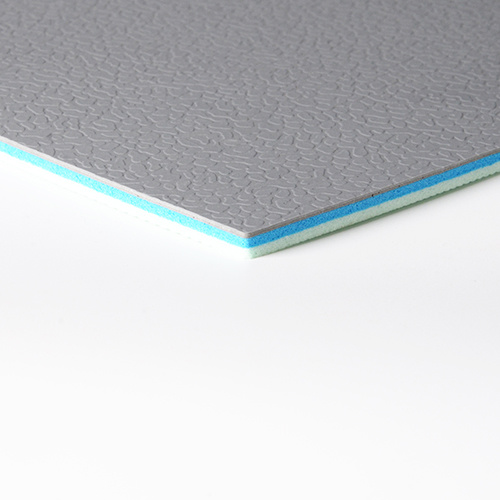

As we go up in size and move away from retail, we can start thinking in terms of perhaps one-third of the cost for liner materials, but certainly, the other related costs are a large factor too. Once we get away from the small garden pond, we as well find that other materials will out-perform EPDM by a large margin – greatly Reinforced Polyethylene (RPE) and as well PVC in most applications. In the matter of pricing, RPE and PVC can be close to the similar cost for a large pond liner. High-density polyethylene (HDPE) is at times suggested because it’s a cheaper material by the square foot; still, it has significant drawbacks in the actual field installation, which is where the true cost of a liner becomes apparent.

The cost-effectiveness of the pond liner is a factor of its proper pricing.

You want non-toxic material for a fish pond, and you want something that won’t degrade promptly with a long-term project. In case the ground is less than ideal, you might either be required to use an underlayment to protect the liner from tearing, or you might be required to coat the bed with a layer of soft soil or sand ahead of setting the liner in place.

The area needed to be covered is pretty enough to calculate and allows enough for an anchoring trench around the perimeter. The virility of terrain is a factor in materials choice. A gently inclining, custom-excavated pond on a golf course or for irrigation might use PVC. Burying this liner to protect from UV degradation will increase its service life from a couple of years to as much as twenty.

Recommended article:How Do Dancing Water Fountains Work?

Benefits and highlights of an Expandable Container House

How to build a wood slat wall?

Geogrid vs. Geotextile: Which Solution is Right for Soil Reinforcement?

Manufacturing Process of Cold Rolled Steel Coil

Types of Outdoor Sports Court Tiles

Benefits of Belleville Washers

For more stable, non-toxic, and difficult applications, RPE is an excellent material. This is a case where the material itself is less a part in strength and puncture resistance than the reinforcement, which arrives from the weave.

Installing a durable pond liner

Installation can be the weakest link in the chain of steps needed to create a durable pond liner. While we use our installation crews, many projects will frequently give less thought to this, often using less than skilled labor on the project. It’s prime not to stress the liner during installation. If it’s going to be buried under a layer of soil/sand, this requires to be done carefully, not putting weight on unburied components of the liner.

The tarpaulin pond liner is primarily used for water retention, involving the lining of lakes, fish farms, garden ponds, and artificial streams in parks and gardens. It is required to be protected from sharp objects below the liner and from being punctured by any objects in the water body.

Protection can be provided with layers of sand, concrete, fibber-matting, geotextile, and other items. Pond lining film is fabricated in rolls of PVC or HDPE and Geomembrane. Strips of liner can be welded together on-site or can be pre-manufactured in our factory. The peak of the pond lining sheet can be rolled over and secured in a trench or it can be fixed to a vertical wall created in brick or concrete.

Each pond liner project is potentially unique and should be treated the same. Even though there are ordinarily accepted standards to use as benchmarks for specifications, we believe a consultation with the supplier upfront is the most effective manner to specify the correct materials and distribution for the project. Here are some of the elements to weigh before you even do your earthwork.

Custom Medicine Cabinets: A Perfect Blend of Functionality and Style

LED Bathroom Mirror: Illuminating Elegance and Functionality

What is a rebar cap?

Advantages of using PUR hot melt adhesive

What are the common uses of chipboards?

Creating Unique Custom Marble Statues: A Journey of Artistic Expression

Digital Water Curtain: A Mesmerizing Fusion of Technology and Art